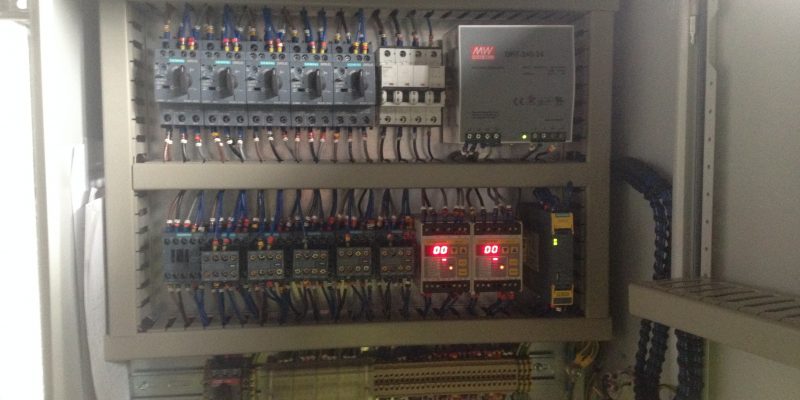

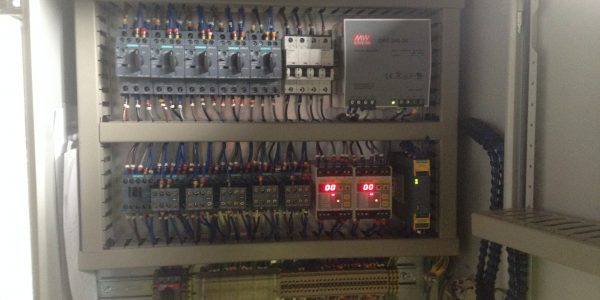

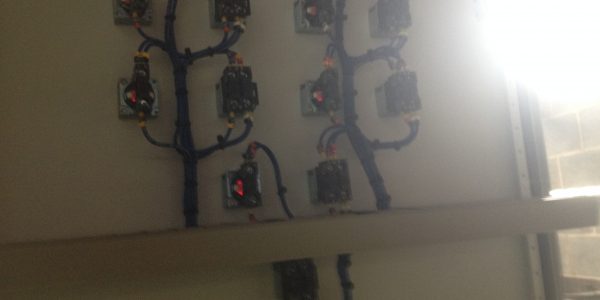

This project involved the design, supply and install of an electrical control panel for the control of 2No chlorite mixing tanks. It consisted of 2No DOL starter for the control of re-circulation / storage tank fill pumps. This was complete with digital lead monitors for dry running protection of the pumps. There were also 2No DOL starters for the control of tank agitators to assist the blending process. Provision was also provided for a standby pump to be plugged into the panel in the event of a failure of the pump.

A stop monitoring system was also incorporated into the system with remote estop stations to shut down the process in the event of an emergency.

Click on the images below for more detail.